Pneumatic AIr Cutters Suppliers

Pneumatic AIr Cutters Suppliers Specification

- Media

- Compressed Air

- Structure

- Double Handle, Compact Design

- Power

- 0.25 kW

- Material

- Aluminum Alloy Body, High Carbon Steel Blades

- Air Consumption

- 6 CFM

- Speed

- 11000 RPM

- Maximum Torque

- 12 Nm

- Blade Type

- Replaceable, Hardened Steel

- Operating Pressure

- 6.2 Bar (90 PSI)

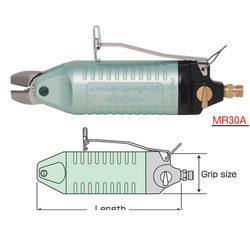

- Overall Length

- 180 mm

- Air Inlet

- 1/4 inch

- Handle Type

- Ergonomic, Non-slip Grip

- Weight

- 350 g

- Cutting Capacity

- Copper Wire Ø 5 mm, Iron Wire Ø 3 mm

- Noise Level

- 75 dBA

- Application

- Industrial Cutting of Wires, Plastic, and Soft Metals

About Pneumatic AIr Cutters Suppliers

Pneumatic Air Cutters - Air Nippers Blades

NILE power cutters are used for innovative applications in

Gold, Silver, Platinum cutting (Jewellery industry)

Plastic cutting (Hard and soft plastics)

Crimping

Breaking

Bending (Washer, Fittings, Parts)

Punching (Sheet Metal parts)

Extending (Tubes, fittings etc.)

Inserting (Circlip etc.)

NILE power cutters are available in more than 100 models depending upon the cutting capacities and requirements in hand operated, machine operated, robot operated and transfer line operation applications. Nile power cutters (Nippers) find innovative applications in Automobile Car, Bike, Vehicle assemblies, White Goods manufacturing, Wire Harness, Electrical and Electronics industries. Nile nipper blades are designed to suit your requirements in various cutting, crimping, and innovative applications. Arhan will provide manufacturing solutions similar to that used in Japanese industries.

***Blades are Sold Separately***

|

Efficient Industrial Cutting Performance

Our pneumatic air cutters are crafted for consistent and rapid cutting tasks in industrial environments. With replaceable, high-carbon steel blades and a robust aluminum alloy body, these tools deliver long-lasting efficiency, particularly for copper and iron wires as well as plastics and soft metals. Their compact design and double-handle structure maximize user control and minimize vibration during extended use.

Ergonomic, User-Friendly Design

The cutters feature an ergonomic grip that is both non-slip and comfortable, reducing strain and enhancing safety during operations. Weighing just 350 grams and measuring 180 mm in length, they are ideal for prolonged use in various settings including manufacturing, electrical work, and maintenance applications.

Supplier for Multiple Business Types Across India

As a trusted supplier, manufacturer, and exporter across India, we provide these pneumatic air cutters to dealers, distributors, wholesalers, retailers, and service providers. Our network ensures prompt delivery, reliable after-sales service, and tailored solutions for diverse industry needs.

FAQs of Pneumatic AIr Cutters Suppliers:

Q: How do these pneumatic air cutters operate in industrial environments?

A: These air cutters utilize compressed air at a pressure of 6.2 Bar (90 PSI) through a 1/4-inch inlet to drive their high-speed motor, which reaches up to 11,000 RPM. This setup ensures efficient cutting of copper, iron wires, and soft metals in industrial settings.Q: What materials can be cut with these pneumatic air cutters?

A: They are suitable for cutting copper wire (up to 5 mm), iron wire (up to 3 mm), plastics, and soft metals. The hardened steel, replaceable blades provide resilience for varied industrial materials.Q: When is it beneficial to use a pneumatic air cutter over manual or electric cutters?

A: Pneumatic air cutters offer superior power, reduced operator fatigue, and faster cutting speed, especially in high-volume and heavy-duty industrial operations. Their ergonomic design also enhances safety and comfort during prolonged use.Q: Where can these pneumatic air cutters be sourced or purchased in India?

A: These cutters are available through authorized dealers, distributors, wholesalers, retailers, and directly from the manufacturer or exporter. Our extensive network spans India, ensuring accessibility for various business types.Q: What is the process to replace blades on these pneumatic air cutters?

A: The blade replacement procedure involves safely disconnecting the cutter from the air supply, releasing the blade housing, removing the worn blade, and installing a new hardened steel blade. Detailed instructions are provided with every product.Q: How does the ergonomic handle benefit users during repetitive cutting tasks?

A: The ergonomic, non-slip grip reduces strain, minimizes accident risk, and provides comfortable handling, making the cutter suitable for repeated or prolonged tasks in industrial environments.Q: What are the main advantages of the double handle compact design?

A: The double handle ensures extra stability and precision during cutting operations, while the compact size allows for maneuverability in tight spaces and easy transport between worksites.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Pneumatic Tools Category

Hand Tools And Cutters Suppliers

Material : Alloy Steel, Carbon Steel, Stainless Steel

Power : 0.51.2 HP

Structure : Ergonomically Designed Handle, Adjustable Jaw

Media : Manual, Pneumatic

Speed : 600012000 RPM

Maximum Torque : 60 Nm

Pneumatic Cutters Air Cutters Suppliers

Material : Stainless Steel Body

Power : 0.5 HP

Structure : Ergonomic OneHanded Operation

Media : Compressed Air

Speed : 12000 RPM

Maximum Torque : 25 Nm

Pneumatic Cutters Air Cutters

Material : Metal

Power : Pneumatic

Structure : Handheld Cutter

Media : Air

Merry Hand Tools And Cutters

Material : Steel

Power : Manual

Structure : Ergonomic Design

Media : Hand Operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry