Test Stand

Test Stand Specification

- Mounting Type

- Bench-top

- Response Time

- <100 ms

- Display Type

- Digital LCD

- Humidity

- 20% - 80% RH

- Equipment Type

- Test Stand

- Max Height

- 1200 mm

- Automation Grade

- Automatic

- Test Range

- 0-5000 N

- Hardness

- Hardened steel structure

- Port Size

- Standard adapter connectors

- Interface Type

- RS232/USB

- Resolution

- 0.01 N

- Application

- Material tensile, compression, holding force and shear test

- Specimen Size

- Customizable

- Operating Voltage

- 220V

- Features

- High precision, Fully automated, Human-machine interface, Real-time display

- Gas Pressure

- 0.6~0.8 MPa

- Temperature

- 5C - 40C

- Measuring Range

- 0-5000 N

- Accuracy

- 1%

- Number of Specimens

- 1

- Power Supply

- AC 220V, 50/60Hz

- Frequency

- 50/60 Hz

- Usage

- Laboratory / Industrial quality inspection

- Capacity

- 5 kN

- Machine Weight

- 80 kg

- Test Speed

- 10-500 mm/min (adjustable)

- Test Width

- 300 mm

- Test Stroke

- 600 mm

- Control Mode

- Digital automatic control

- Safety Protection

- Emergency stop button and limit protection

- Installation

- Ready to use, minimal assembly

- Test Method

- Tensile, Compression, Peel, Shear

- Drive Mode

- Servo motor drive

- Color

- White/Blue finish

- Operating Language

- English/Chinese selectable

- Load Cell Brand

- Branded precision sensor

- Software Compatibility

- PC software with report export

- Frame Material

- Powder coated steel

About Test Stand

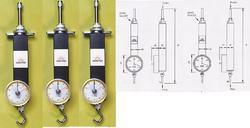

TEST STAND

Features:

* Optional; test stand, be connected

with FG-5000A, FG-20KG,

FG-5000A-232, FG-20KG-232,

FG-5005, FG-5020.

whole system will be a useful

tool for material's tension and

compression analysis.

* Size : 650 x 250 x 230 mm.

* Net Weight : 6.9 Kg.

Versatile Testing Applications

The Test Stand caters to multiple testing requirements including material tensile, compression, holding force, and shear test. With a customizable specimen size and a broad measuring range (05000 N), it adapts to diverse material standards in both laboratory and industrial settings.

High-Precision Performance

Equipped with a branded precision load cell and advanced servo motor drive, the test stand delivers high-precision results with a measurement accuracy of 1% and a fine resolution of 0.01 N. The digital automatic control and real-time display streamline operations and data accuracy.

User-Friendly and Automated

The operator benefits from fully automated controls and a human-machine interface. Software runs in English or Chinese, and report export functionality enhances traceability. Installation is straightforward, with minimal assembly required, making it ready for immediate use.

Robust Safety and Durability

Safety features include an emergency stop button and limit protection. The powder-coated, hardened steel structure ensures durability in demanding environments. With a machine weight of 80 kg, the unit is stable for rigorous testing, yet manageable for bench-top mounting.

FAQs of Test Stand:

Q: How is the Test Stand controlled and operated?

A: The Test Stand uses a servo motor drive with digital automatic control. Operation is user-friendly via its human-machine interface, and the system supports both English and Chinese languages. All settings, speed, and test parameters are accessible through the digital LCD display and PC software.Q: What safety features are incorporated into this equipment?

A: The Test Stand is equipped with an emergency stop button and limit protection to safeguard users during operation. Its sturdy powder-coated steel frame further enhances safety and equipment resilience in laboratory or industrial environments.Q: When should this test stand be used in material testing?

A: This stand is ideal for material tensile, compression, holding force, and shear testing, suitable at any phase where precise measurement and automated testing are neededwhether in production quality assurance or R&D laboratories.Q: Where is the Test Stand typically installed and used?

A: The machine is designed for bench-top mounting, making it suitable for laboratory and industrial quality inspection facilities. Minimal assembly is required, and it is ready to use upon installation.Q: What is the process for operating tests with this equipment?

A: Install the specimen (customizable size) and select the desired test mode. Adjust the test speed (10500 mm/min), set parameters through the digital interface, and initiate the automated testing process. Results are displayed in real-time and can be exported via PC software.Q: What are the main benefits of using this automated test stand?

A: Key benefits include high-precision measurements, automated operation, fast response time (<100 ms), multi-language support, and straightforward data export. Its robust safety, minimal manual intervention, and durable structure ensure reliable and efficient testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Force Gauge Category

Push Pull Force Gauges Dealers

Resolution : 0.01 N

Capacity : 1 kg to 500 kg

Test Range : 0500 N

Usage : Laboratory, Industrial Inspection

Display Type : Digital / Mechanical Analog

Mounting Type : Handheld or Stand Mounted

Digital Force Gauge Suppliers

Resolution : 0.01 kgf

Capacity : 100 kgf

Test Range : Up to 100 kgf

Usage : Industrial and laboratory applications

Display Type : Digital

Mounting Type : Handheld

Push Pull Force Gauges Distributors

Resolution : 0.01 kg

Capacity : 20kg 40kg

Test Range : 20kg / 40kg maximum capacity

Usage : Force measurement for industrial applications

Display Type : LCD

Mounting Type : Handheld

Push Pull Force Gauges Suppliersa

Resolution : 0.1N

Capacity : 0500N

Test Range : 0500N

Usage : Force measurement in mechanical testing and quality control

Display Type : Digital

Mounting Type : Handheld or mounted with external adapters

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry