Dew point sensor

Dew point sensor Specification

- Application

- Measurement of Dew Point in Compressed Air and Industrial Gases

- Port Size

- 1/8 to 1/2 inch NPT

- Mounting Type

- In-line / Wall Mounted

- Power Supply

- 24V DC / 230V AC, 50 Hz

- Operating Voltage

- 24 V DC / 230 V AC

- Equipment Type

- Dew Point Sensor

- Temperature

- -40C to +60C

- Measuring Range

- -100C to +20C dew point

- Accuracy

- 2C dew point

- Gas Pressure

- Max. 16 bar

- Automation Grade

- Automatic

- Test Range

- -100C to +20C dew point

- Interface Type

- 4-20 mA, RS485, MODBUS

- Features

- Fast Response, Stable Output, Compact Design, Easy Installation, Maintenance-Free

- Humidity

- 0 to 100% RH (Relative Humidity)

- Response Time

- t90 < 30 s

- Display Type

- Digital LCD / LED Display

- Resolution

- 0.1C dew point

- Frequency

- 50/60 Hz

- Usage

- Industrial Process Monitoring, Compressed Air Dryers, Gas Analysis

- Machine Weight

- Approx. 120 g

- Control Mode

- Digital Microprocessor Based

- Cable Length

- 2 meters

- Protection Class

- IP65

- Operating Pressure

- 0 to 1 MPa

- Calibration Interval

- Recommended 12 Months

- Dimensions

- 120 x 30 x 30 mm

- Sensor Element

- Advanced polymer or ceramic technology

- Ambient Conditions

- Non-condensing

- Storage Temperature

- -20°C to +70°C

- Output Signal

- 4-20 mA, RS485, Modbus

- Housing Material

- Aluminum alloy

About Dew point sensor

The FA 550 is ideally suited for outdoor dew point measurement and reliably determines dew points even under harsh industrial conditions.

Application examples

- Dew point measurement in compressed air systems after adsorption dryers, membran dryers or refrigeration dryer

- Residual moisture measurement and dew point measurement in gases such as: oxygen, nitrogen, argon, hydrogen, natural gas, biogas...

Accurate Dew Point Monitoring for Industrial Applications

Efficiently monitor dew point in compressed air and industrial gases using this automatic, microprocessor-based sensor. Its fast response and broad measurement range enhance safety and process control across diverse settings such as gas analyzers and air dryers.

Rugged and Flexible Design for Easy Integration

Housed in an aluminum alloy enclosure with IP65 protection, this dew point sensor offers reliable performance in harsh environments. With multiple signal interfaces, a digital LCD/LED display, and versatile mounting sizes, it seamlessly fits in various industrial systems.

Low Maintenance and User-Friendly

Designed for hassle-free use, this sensor is maintenance-free and offers stable, long-term output. Its compact design and 2-meter cable length enable flexible installation, while an annual calibration interval ensures sustained accuracy.

FAQs of Dew point sensor:

Q: How does the dew point sensor measure moisture in gases?

A: The sensor utilizes advanced polymer or ceramic technology to detect the dew point by measuring the amount of moisture present in compressed air or industrial gases. It provides accurate readings with a resolution of 0.1C and a response time of less than 30 seconds.Q: What are the recommended calibration procedures for this sensor?

A: It is advised to calibrate the sensor every 12 months to maintain optimal performance and accuracy (2C dew point). Calibration can be performed using standard procedures provided by the manufacturer, dealer, or authorized service providers.Q: When should this dew point sensor be used in industrial processes?

A: The sensor is ideal for continuous monitoring of critical points in compressed air dryers, process control systems, and gas analysis applications where dew point measurement is essential for product quality, operational safety, and equipment longevity.Q: Where can the sensor be installed within an industrial setup?

A: Thanks to its in-line or wall-mounted design and multiple port sizes (1/8 to 1/2 inch NPT), the sensor can be installed directly in piping systems, monitoring panels, or wherever dew point measurement is necessary in industrial settings.Q: What is the installation process for this dew point sensor?

A: Installation is straightforward due to its compact form factor, 2-meter cable, and standard mounting interfaces. Simply connect the sensor to the desired location, supply it with 24V DC or 230V AC (50/60 Hz), and link to your monitoring system via the preferred interface.Q: How does this sensor benefit industrial operations?

A: Timely and accurate dew point readings help prevent equipment corrosion, ensure product quality, and reduce maintenance costs. Its fast response, stable output, and automatic operation allow for continuous, worry-free monitoring in demanding environments.Q: What are the ambient and operating conditions for optimum sensor performance?

A: The sensor is designed for non-condensing environments with ambient temperatures from -40C to +60C, and gas pressures up to 16 bar, ensuring robust operation across a wide spectrum of industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CS Instruments Category

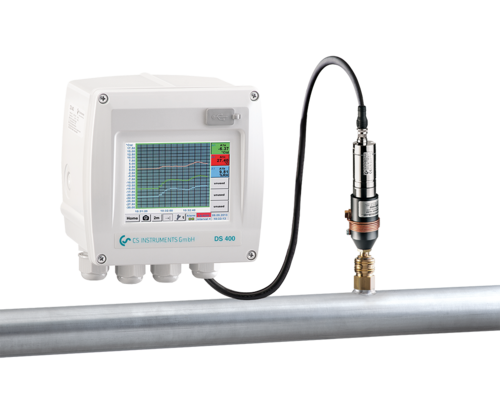

Dew Point Measurement

Features : High Sensitivity, Portable, Easytouse, Reliable Readings

Usage : Industrial / Laboratory

Application : Dew point measurement for gases, air, compressed air, and dryers

Mounting Type : Wall or Panel Mount

Power Supply : 220 V AC

Humidity : Up to 95% RH

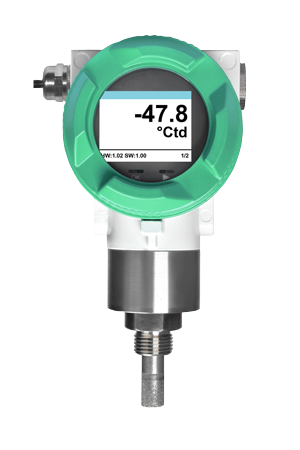

Stationary Dew Point

Features : Fast response, robust design, real time monitoring

Usage : Laboratory and Industrial

Application : Industrial Gas Analysis, Pharmaceutical, Food Processing

Mounting Type : Fixed

Power Supply : 220V AC, 50Hz

Humidity : 90% RH

Industrial Dew Point Sensor

Features : Robust stainless steel body, fast response, high accuracy

Usage : Continuous dew point monitoring

Application : Industrial process monitoring

Mounting Type : Inline / Panel mount

Power Supply : 1224V DC

Humidity : 0100% RH

Portable Dew Point

Features : Accurate

Usage : Industrial

Application : Testing & Measurement

Mounting Type : Free Stand

Power Supply : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry