Industrial Dew Point Sensor

Industrial Dew Point Sensor Specification

- Max Height

- 150 mm

- Temperature

- -40C to +60C

- Automation Grade

- Automatic

- Equipment Type

- Industrial Dew Point Sensor

- Mounting Type

- Inline / Panel mount

- Features

- Robust stainless steel body, fast response, high accuracy

- Gas Pressure

- Up to 10 bar

- Test Range

- -80C to +20C dew point

- Application

- Industrial process monitoring

- Operating Voltage

- 12-24V DC

- Port Size

- 1/4 NPT

- Humidity

- 0-100% RH

- Power Supply

- 12-24V DC

- Display Type

- Digital LED

- Accuracy

- 2C dew point

- Response Time

- <30 seconds

- Resolution

- 0.1C

- Number of Specimens

- Single

- Measuring Range

- -80C to +20C dew point

- Interface Type

- RS485 / 4-20mA

- Usage

- Continuous dew point monitoring

- Capacity

- Continuous measurement

- Machine Weight

- 250 g

- Control Mode

- Automatic

- Operating Pressure

- 0 to 5 MPa

- Calibration

- Factory calibrated, ISO traceable

- Sensor Type

- Capacitive Polymer Sensor

- Ambient Temperature

- -40°C to +70°C

- Storage Temperature

- -40°C to +85°C

- Output Signal

- 4-20 mA/RS485 (Modbus RTU)

- Material

- Stainless Steel Body

- Ingress Protection

- IP65

- Cable Length

- 2 meters (standard)

About Industrial Dew Point Sensor

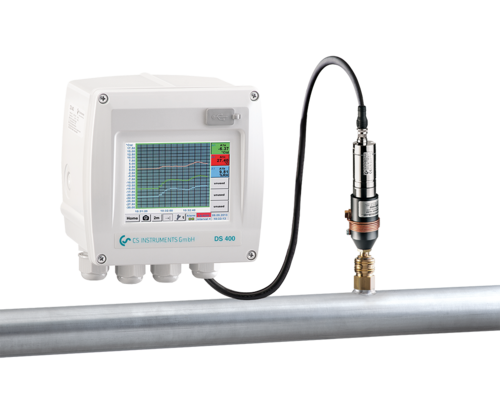

FA 500 is the ideal dew point sensor with integrated display and alarm relay for refrigeration, membrane and desiccant driers.

Special features:

- NEW: Modbus-RTU interface

- NEW: Higher resolution of sensor signal caused by the improved evaluation electronics

- NEW: Sensor diagnosis on site with a portable device or CS Service Software

- Integrated display

- Threshold value adjustable via keypad alarm relay (max. 60 VDC, 0,5 A)

- Pressure-tight up to 350 bar (special version)

- Extreme long-term stability

- Quick response time

- 4...20 mA analogue output

- 2 versions: Refrigeration driers and desiccant driers

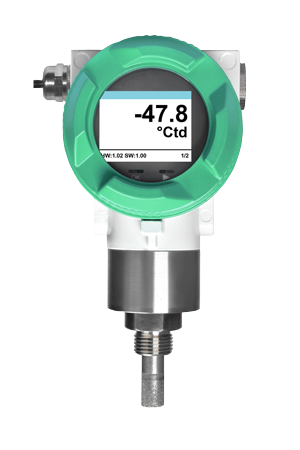

Superior Durability and Precision

Built with a stainless steel housing and rated IP65, the Industrial Dew Point Sensor stands up to harsh operating conditions. The advanced capacitive polymer sensing element ensures stability and high accuracy, offering 2C dew point precision and 0.1C resolution. Factory calibration ensures ISO traceability for dependable, repeatable results in continuous industrial process applications.

Versatile Integration and Easy Operation

Compatible with both inline and panel mounting, this sensor seamlessly integrates into existing systems using 4-20 mA or RS485 (Modbus RTU) output signals. The automatic control mode and fast response enable real-time monitoring, while the digital LED display provides clear readings for quick on-site assessment. Supported by a 2-meter standard cable for flexible installation.

Ideal for Demanding Industrial Applications

The sensor accommodates a broad measuring range (-80C to +20C dew point) and tolerates extreme ambient temperatures from -40C to +70C. Its robust design and continuous measurement capability make it an excellent choice for industrial environments that demand consistent performance, such as manufacturing, chemical processing, and gas monitoring.

FAQs of Industrial Dew Point Sensor:

Q: How is the Industrial Dew Point Sensor installed in a process system?

A: The sensor is designed for easy installation using a 1/4 NPT port and can be mounted either inline or on a control panel, depending on your requirement. Its 2-meter cable and compact 150 mm height simplify integration into existing piping or monitoring setups.Q: What makes the capacitive polymer sensor technology beneficial for industrial applications?

A: Capacitive polymer sensors offer high stability, rapid response, and immunity to contamination, ensuring reliable dew point measurement even in demanding industrial environments. This technology ensures accuracy and long-term consistency in continuous monitoring.Q: When is recalibration necessary for this dew point sensor?

A: The sensor is factory calibrated and ISO traceable, ensuring initial accuracy. Recalibration intervals depend on the usage environment and company quality policies, but routine annual checking is recommended for optimal performance in critical applications.Q: Where can this sensor be used within an industrial facility?

A: It is suitable for installation in process lines, control panels, or any section requiring dew point measurement, especially where robust, continuous monitoring is essential. Typical users include industries such as manufacturing, chemical plants, and compressed air systems.Q: What type of output signals does this sensor provide for data integration?

A: For maximum flexibility, the sensor features both 4-20 mA analog output and RS485 digital communication using the Modbus RTU protocol, allowing easy integration with most industrial automation and monitoring systems.Q: How does continuous monitoring with this sensor benefit industrial processes?

A: Continuous dew point monitoring helps ensure consistent product quality, prevent equipment corrosion, and detect moisture ingress early, thereby minimizing operational downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CS Instruments Category

Dew Point Measurement

Usage : Industrial / Laboratory

Features : High Sensitivity, Portable, Easytouse, Reliable Readings

Mounting Type : Wall or Panel Mount

Power Supply : 220 V AC

Application : Dew point measurement for gases, air, compressed air, and dryers

Response Time : 10 s

Stationary Dew Point

Usage : Laboratory and Industrial

Features : Fast response, robust design, real time monitoring

Mounting Type : Fixed

Power Supply : 220V AC, 50Hz

Application : Industrial Gas Analysis, Pharmaceutical, Food Processing

Response Time : 5 seconds

Dew point sensor

Usage : Industrial Process Monitoring, Compressed Air Dryers, Gas Analysis

Features : Fast Response, Stable Output, Compact Design, Easy Installation, MaintenanceFree

Mounting Type : Inline / Wall Mounted

Power Supply : 24V DC / 230V AC, 50 Hz

Application : Measurement of Dew Point in Compressed Air and Industrial Gases

Response Time : t90 < 30 s

Portable Dew Point

Usage : Industrial

Features : Accurate

Mounting Type : Free Stand

Power Supply : Electric

Application : Testing & Measurement

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry