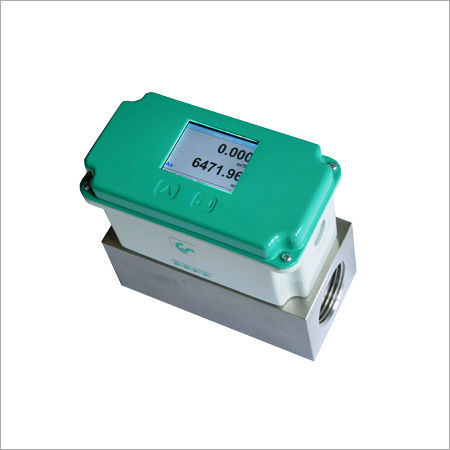

VA 525 - Compact in-line flow sensor

VA 525 - Compact in-line flow sensor Specification

- Mounting Type

- Inline, directly into pipe system

- Features

- Bidirectional measurement, compact design, easy installation, maintenance-free

- Equipment Type

- Compact in-line flow sensor

- Humidity

- Max. 90% RH (non-condensing)

- Automation Grade

- Automatic

- Display Type

- LCD digital display

- Operating Voltage

- 24 V DC

- Application

- For compressed air and non-corrosive gases

- Interface Type

- Analog output (420 mA), Pulse, Modbus RTU/RS485 (optional)

- Measuring Range

- 20 to 5,000 l/min (depending on port size)

- Port Size

- G 1/2, 1/4, 3/8 (varies by model)

- Response Time

- 50 ms

- Temperature

- -20C to +70C (ambient)

- Power Supply

- 24 V DC 10%

- Accuracy

- 1.5% of measured value 0.3% F.S.

- Gas Pressure

- Max. 16 bar (232 psi)

- Resolution

- 0.1 l/min

- Usage

- Flow measurement in compressed air systems

- Machine Weight

- Approx. 200 g (varies with port size)

- Control Mode

- Digital, Automatic

- Protection Class

- IP65 (dust and water jet protected)

- Straight Pipe Requirement

- Minimal or none required due to sensor design

- Data Logging

- Integrated totalizer function (resettable/non-resettable)

- Electrical Connection

- M12 (4-pin) connection

- Media Compatibility

- Dry, clean, non-corrosive gases

- Body Material

- Anodized aluminum (sensor body); Stainless steel available on request

- Optional Accessories

- Panel mounting kit, remote display, power adapter

- Pressure Loss

- < 0.1 bar at max. flow

- Display Units

- Selectable: l/min, m³/h, cfm

About VA 525 - Compact in-line flow sensor

- Current consumption in m³/h, l / min, ...

- Total consumption (meter reading) in m³, l, kg

- Temperature measurement

- Optional: Pressure measurement

- Compact, small design - for use in machines, behind maintenance unit at the end user

- Optionally with classic analogue signals (4...20 mA and pulse) or digital interfaces such as Modbus RTU, Ethernet (also PoE), M-Bus

- All interfaces are programmable via the display

Advanced Measurement for Automation

The VA 525 delivers precise digital flow monitoring for compressed air and other non-corrosive gases. Its high accuracy (1.5% of measured value 0.3% F.S.) and minimal straight pipe requirement simplify installation in various layouts. With fast response times and selectable display units, this sensor integrates seamlessly into automation systems, supporting enhanced process control and energy management.

User-Friendly and Versatile Design

Engineered with a compact, maintenance-free design, the VA 525 can be mounted directly in-line without the need for lengthy straight pipe sections. Its IP65-rated housing protects against dust and water jets, making it suitable for demanding environments. The sensor is compatible with different port sizes and features optional accessories such as remote displays and panel mounting kits for flexible deployment.

Reliable Data and Connectivity Options

Equipped with an M12 (4-pin) connector and supporting analog output (420 mA), pulse, and Modbus RTU/RS485 (optional), the VA 525 facilitates easy integration with existing control systems. The integrated totalizer enables detailed consumption logging, while the LCD display presents real-time flow information in user-selectable units.

FAQs of VA 525 - Compact in-line flow sensor:

Q: How does the VA 525 flow sensor operate and what media is it suitable for?

A: The VA 525 uses a compact, inline design to measure the flow of dry, clean, non-corrosive gases, including compressed air. It is not appropriate for liquids or corrosive gases.Q: What are the installation requirements and where can the VA 525 be mounted?

A: Thanks to its innovative design, the VA 525 needs minimal or no straight pipe lengths, enabling direct in-line installation within your pipeline system. It is suitable for new and retrofit setups in various industrial settings.Q: When should I use the VA 525s resettable and non-resettable totalizer functions?

A: The resettable totalizer is ideal for measuring gas flow within a specific period or batch, while the non-resettable totalizer provides cumulative consumption data over the instruments lifetime, assisting with long-term monitoring or auditing.Q: What are the main benefits of using the VA 525 for compressed air applications?

A: Key advantages include high accuracy, a fast digital response ( 50 ms), maintenance-free operation, and robust IP65 protection. Its versatile output options and real-time LCD display improve energy efficiency and process control in automation environments.Q: How does the sensor interface with control systems and what data can be accessed?

A: Connection is via an M12 (4-pin) plug, supporting analog (420 mA), pulse, and optional Modbus RTU/RS485 outputs. Users can monitor instantaneous flow rates, totalized flow, and choose from units like l/min, m/h, or cfm directly on the LCD.Q: What port sizes and operating conditions are supported by the VA 525?

A: The sensor supports G 1/2, 1/4, and 3/8 port sizes (varies by model), functions under pressures up to 16 bar, and sustains operation in ambient temperatures from -20C to +70C and humidity up to 90% RH (non-condensing).Q: Where can the VA 525 be sourced in India, and who typically uses this equipment?

A: The VA 525 is available in India through dealers, distributors, exporters, manufacturers, and retailers. It serves industries requiring precise flow measurement, including factories, energy managers, process engineers, and automation professionals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meter Category

Chart Recorder

Usage : Recording process parameters

Power Supply : 230 V AC, 50 Hz

Mounting Type : Panel Mounted

Features : Longterm Data Recording

Application : Industrial Data Logging

Control Mode : Manual/Automatic

VA 570 - Flow meter with integrated measuring section

Usage : Industrial, process control, energy management

Power Supply : 24 V DC (1830 V DC)

Mounting Type : Inline mounting with integrated measuring section

Features : Integrated measuring section, rugged industrial design, easy installation, no moving parts, low pressure loss, maintenancefree

Application : Measurement and monitoring of compressed air and noncorrosive gases

Control Mode : Microprocessor controlled

VA 500 - Flow sensor for compressed air and gases

Usage : Inline or insertion flow measurement in pipes/ducts

Power Supply : 1836 V DC

Mounting Type : Insertion type

Features : Bidirectional measurement, easy installation, IP65 protected, menu operation via touch buttons

Application : Measurement of compressed air and technical gases

Control Mode : Digital/Analog Output control

Digital Process Meter

Usage : Industrial process measurement

Power Supply : 230V AC, 50/60Hz

Mounting Type : Panel Mount

Features : High brightness LED, Multirange input, Overrange indication, Compact design

Application : Measuring and indicating process signals

Control Mode : Manual/Automatic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry